Following the original by JF3HZB (PW October 2022 p56) I have bodged mine sort of based on the original

https://github.com/tjlab-jf3hzb/Digital_VFO_with_analog_dial

https://tj-lab.org/2019/02/17/vfo5/

I will use for bench signal source and an older direct conversion radio setup I have.

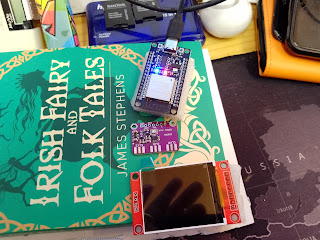

The ESP32 I used seems to be a bit different.

The upload speed 115200, 240MHz, 40Mh flash, 4MB flash

Anyway programmed it.

I used a 2" rotary controller as per the PW article. Ruler and JLCPCB squeaky duck for size comparison.